No matter in sample making or mass production, all the materials and process are using the latest inspection technology and equipment for monitoring and data filing. From temperature and humidity control for the rubber material in warehouse, to material inspection of each batch, observation and tracking of each production molding machine parameters, and visual inspection of finished products and actual quantity check, also including statistical process control method, all the above we do to keep the consistency of the company’s production quality.

SBT's test equipment is used not only to improve oil seal design continuously, but also for the existing and newly developed materials, and even extended its application to OEM material analysis and confirmation of international standard with customers.

Mostly the company's test instruments are capable of doing functional application test on oil seal under good settings circumstances, such as speed adjustment, temperature change, pressure setting, dynamic eccentricity and divagation of the hole, etc.

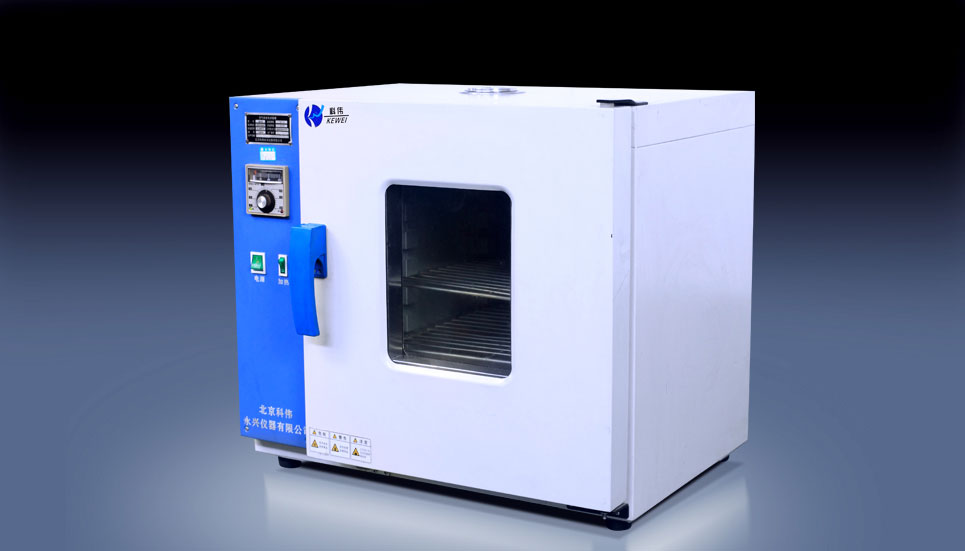

Test all the raw materials before its storage, and issue a report of raw materials characteristics, compare with the original material physical property report, put in storage if test value matches.

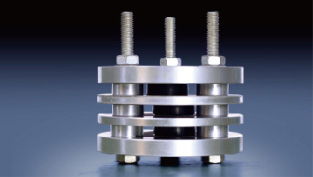

After mold development completed or mold cleaning finished, we do inspection on the mold full size to ensure quality consistency of every product.

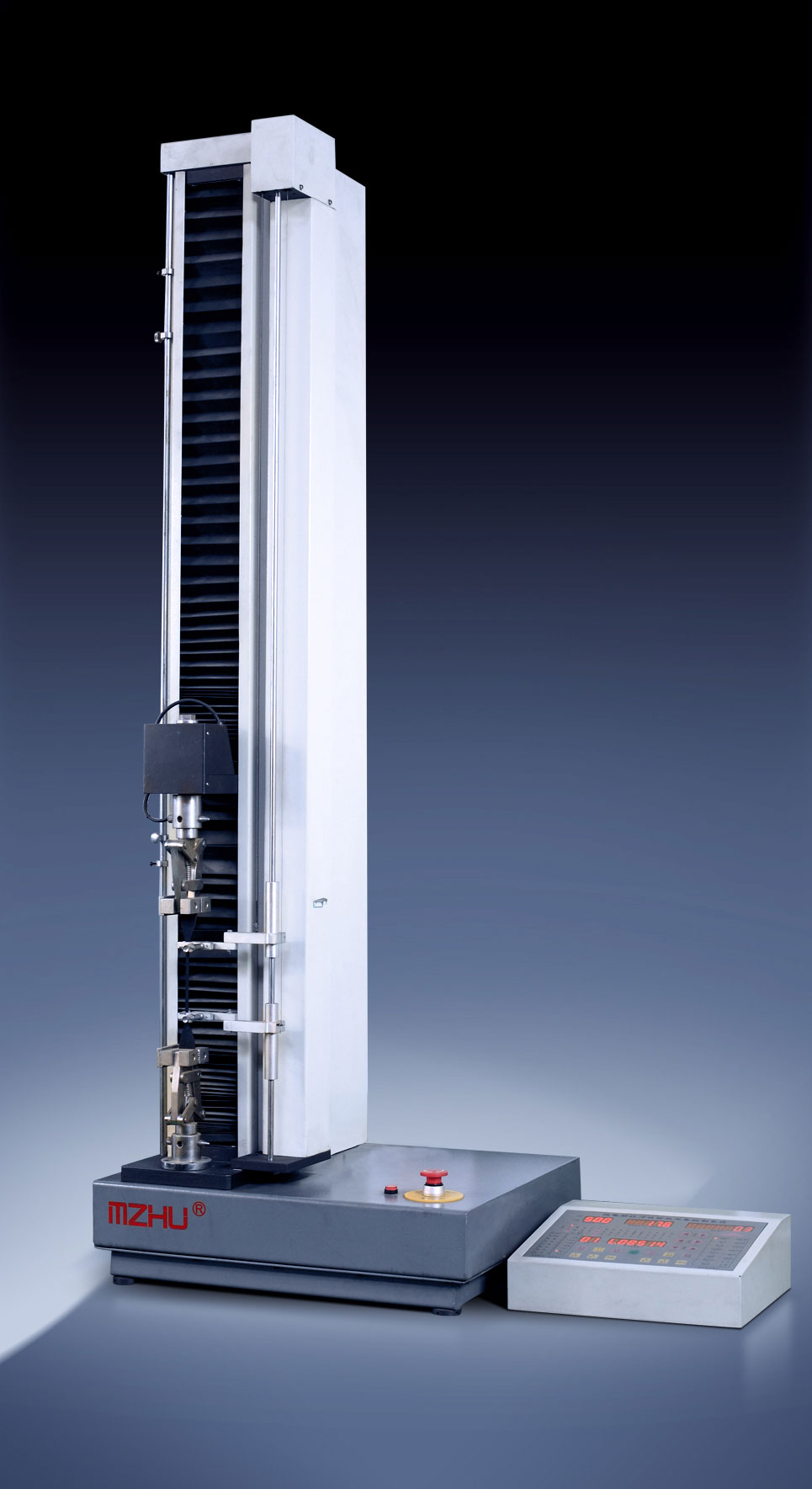

Tensile strength test machine

During production process, inspectors will do inspection for the semi-finished products at fixed time to ensure a rational workmanship and to control the defect rate within a reasonable range.

Quality department will do appearance sample inspection on each batch of products.

Optical inspection machine assures 100% qualification of products appearance and size.

Oil seal rotation performance test machine